Support

After safe arrival of your baler, you are handed over to Orkel’s experienced technicians, who will be responsible for commissioning your machine. For any queries, such as machine settings, technical assistance, spare parts, or simply baling advice, our technicians will gladly assist you over phone or by email – customer service is important to us!

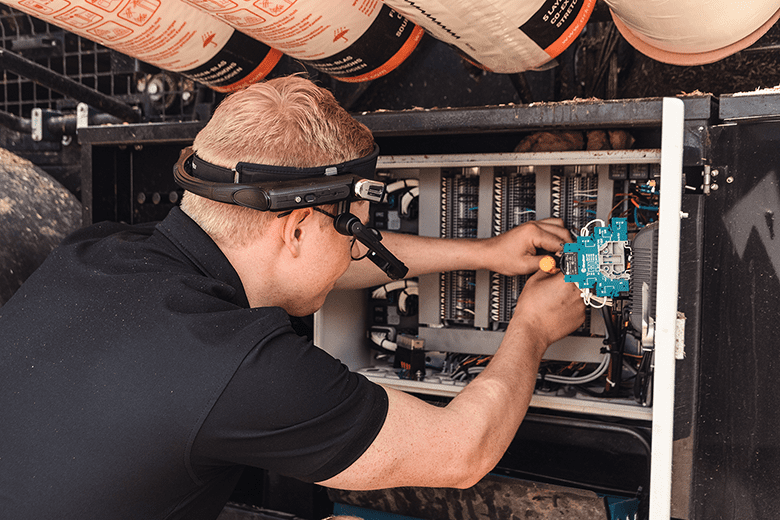

LiveAssist

The LiveAssist device is a head worn device which you may use to communicate directly with an Orkel service technician online. As you are wearing the device, the Orkel technician can see your environment through your eyes and in turn efficiently describe the necessary steps to solve a potential issue. This is efficient and problem solving customer service, that simplifies potential challenges.

Parts and accessories

Discover our Spare Parts and Accessories section. With warehouses across the globe, including a significant inventory in Norway, accessing the parts you require is effortless. Have questions? Our Norwegian experts are on hand to assist you. Explore our range for quality parts and accessories at Orkel.

Find your local technician

Locate your nearest point of contact on the map!

Instructional videos

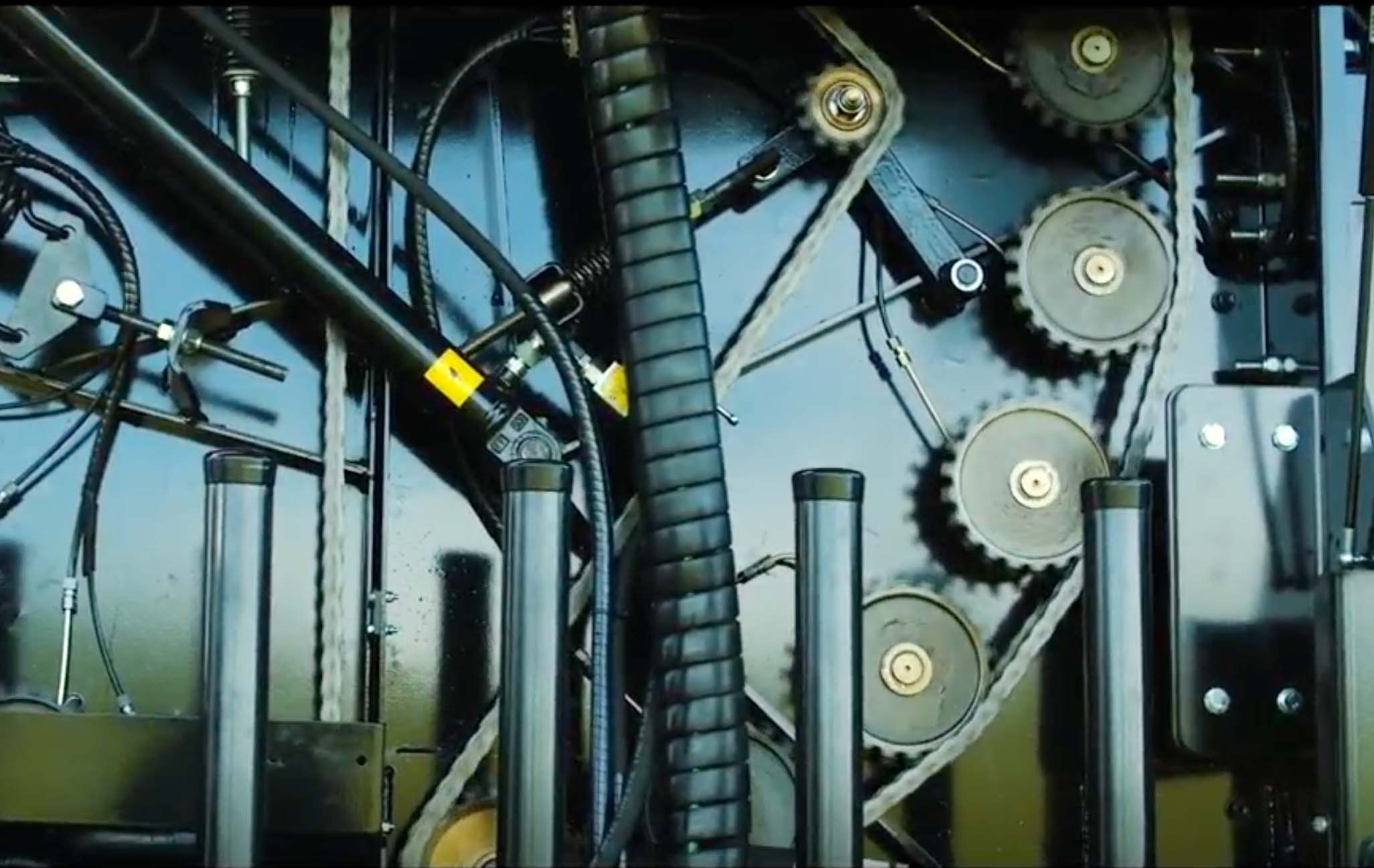

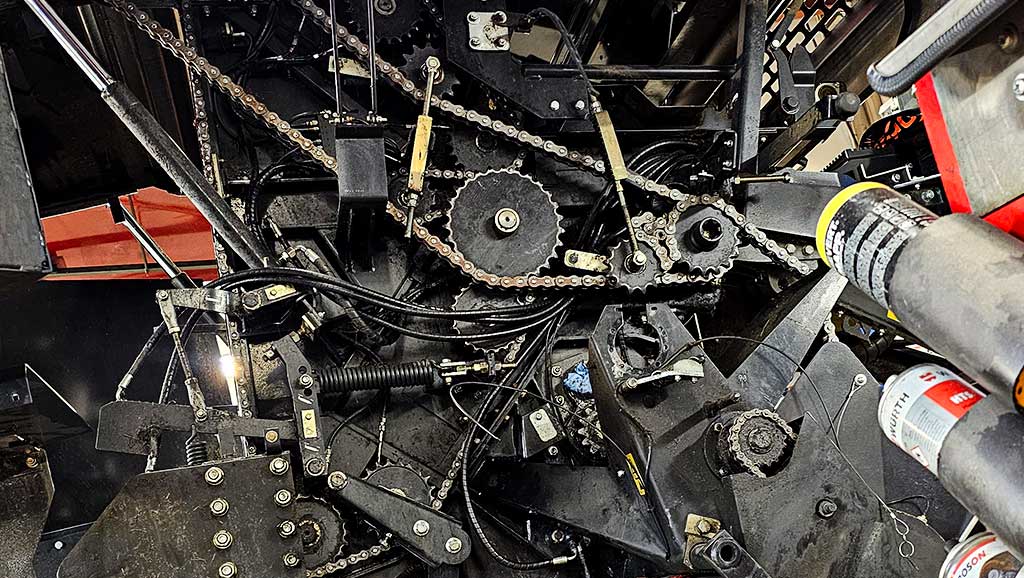

Daily maintenance Orkel balers

Daily maintenance is important to ensure a long lifetime and smooth operation of your Orkel baler. In this video we show you what to check on a daily basis.

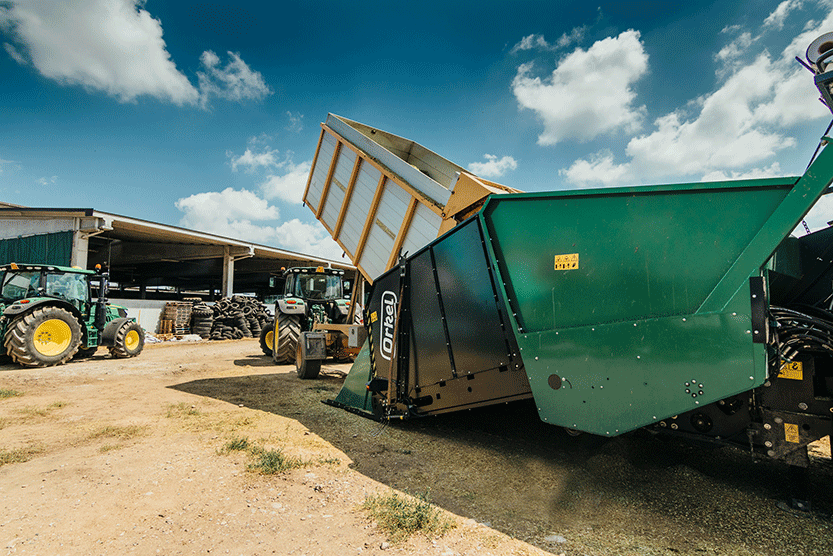

Operating the F25 feed hopper

A quick guide on how to operate the F25 feed hopper on the Dens-X baler.

Wrapper arms and wrap table speed

Learn how to adjust the speed of the wrapper arms and wrap table on the Orkel X-generation balers.

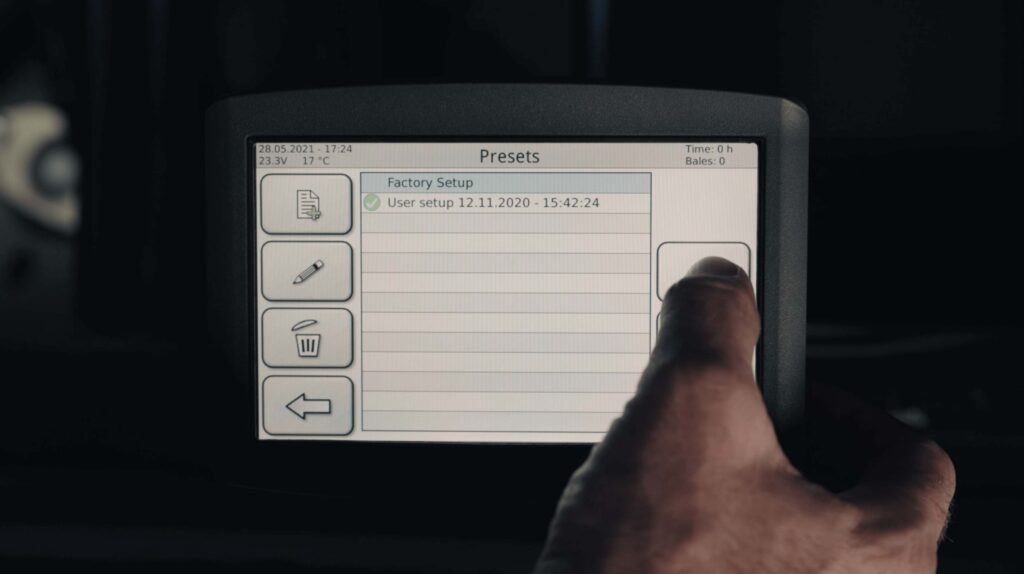

Intro to the Orkel Touch Control System

In this video you will learn the basics of the Orkel Touch Control system found on the X-series Orkel balers.