We have introduced a new Compactor model – the Dens-X PRO, the latest upgrade to our proven X-Generation platform. With a wide range of targeted upgrades, this machine is faster, stronger, smarter and more reliable than ever before.

The Dens-X PRO is developed for farmers and contractors who focus on one key thing: efficient working days. Higher capacity, smoother material flow and smarter operation mean more bales per hour, less downtime and better use of time and resources.

Tested in the Field

One of the main improvements with the Dens-X PRO is increased capacity – something that is quickly noticeable in real operation.

Orkel dealer Jef from Belgium, one of the first to test the Dens-X PRO in the field, describes the difference clearly:

“It’s a totally new machine. You feel the improvement right away.”

During baling, the machine reacts faster and maintains a smooth and steady material flow, even with heavy material.

“The machine reacts faster, and the material flow stays smooth, even under high load,” Jef explains.

In real-world operation, the Dens-X PRO can produce up to 70 bales per hour, depending on type of material and operating conditions.

Improved Material Flow – A Key Factor Behind Higher Capacity

To achieve higher and more stable output, we have focused heavily on material flow into the compaction chamber. Several key upgrades ensure that material moves evenly and smoothly through the machine. Together with faster wrapping, these improvements are key factors behind the higher capacity of the Dens-X PRO.

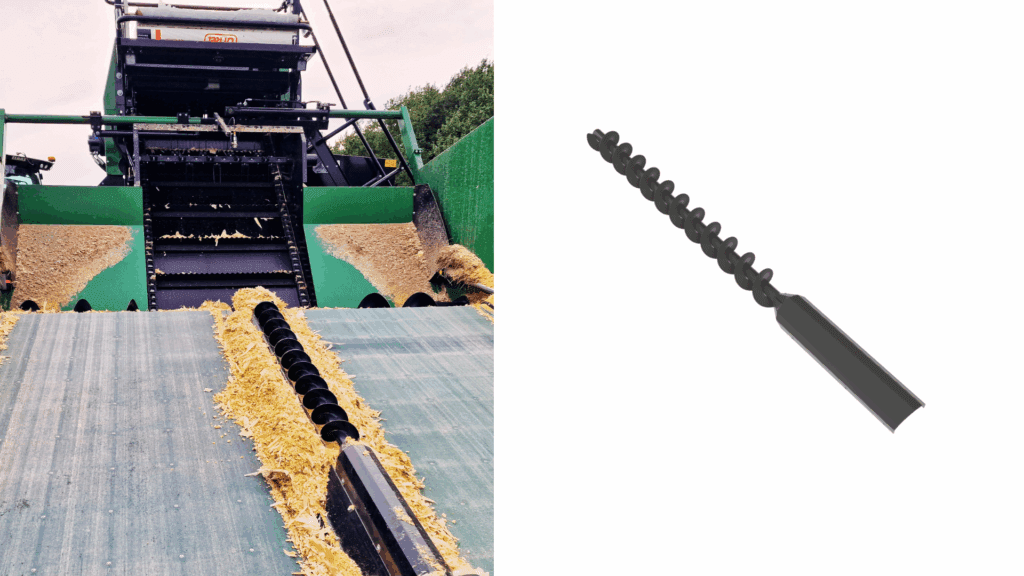

Upgraded Feed Hopper with Center Auger

The feed hopper is now equipped with a center auger that ensures smooth and even material distribution. This allows material to be fed into the system in controlled amounts, improving both capacity and reliability.

In addition, the feed system moves material more effectively towards the elevator, ensuring steady feeding even with demanding materials such as maize and long fibers.

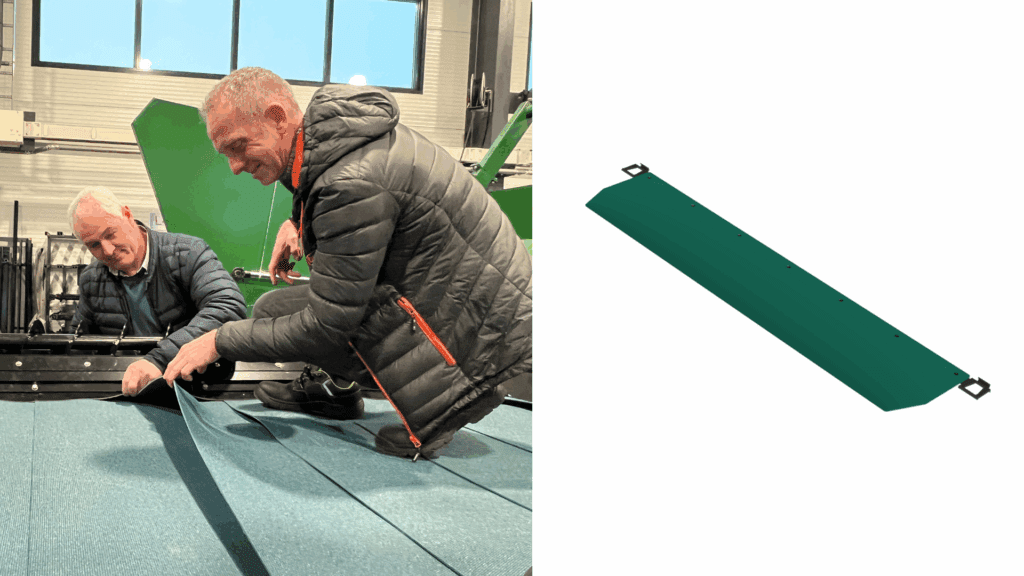

Segmented Belts – Better Flow and Lower Maintenance Costs

The feed hopper now uses segmented belts. These belts contribute to smoother material flow and also make maintenance more cost-efficient.

Instead of replacing a complete belt, operators can replace only the worn segments. This reduces maintenance time, lowers spare part costs and increases overall uptime.

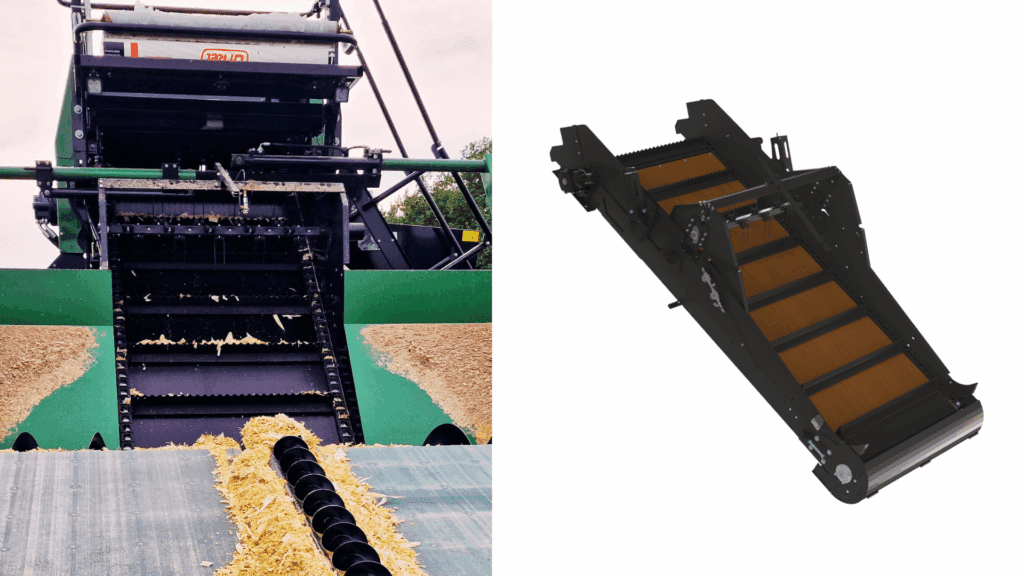

Stronger Elevator with Even Material Distribution

The Dens-X PRO features a new and stronger dual-motor elevator, designed to handle higher loads without slowing down. Combined with the elevator rotor, material is fed in even quantities, preventing overloads and ensuring stable feeding to the compaction chamber.

If material overload should occur, the machine is now equipped with an automatic restart function. This allows the compactor to restart operation on its own, reducing the need for operator intervention and keeping work moving.

The video below shows the Dens-X PRO upgrades in use.

Faster Wrapping and WideFilm Boost

Once the bale is compacted into a dense bale, the Dens-X PRO applies wide film. With the new WideFilm Boost, the chamber speed is increased, allowing the bale to rotate faster during wide film application.

Afterwards, wrapping with round bale film is also completed at a higher speed. Together, these improvements reduce cycle time and further increase total capacity.

Lower Operating Costs and Better Cost Efficiency

In addition to higher capacity, the Dens-X PRO is designed to be more cost-efficient to operate.

Key cost benefits include:

- Reduced plastic use on the widefilm, typically around 20%, depending on material

- Segmented belts that lower maintenance and replacement costs

- Higher output per hour, moving more tonnes with the same machine

- Smarter functions that reduce the need for operator intervention

Together, these factors help lower the cost per bale and improve the overall return on investment.

Smarter Bales with BaleID

The Dens-X PRO can also be equipped with BaleID, Orkel’s digital bale identification system. Each bale is automatically labeled with a QR code, giving easy access to bale data through the BaleID app.

BaleID provides better overview, improved documentation and full traceability of each bale – adding value beyond the baling process itself and supporting more efficient handling and logistics.

Want to learn more about the Dens-X PRO?

Contact us to learn more about the Dens-X PRO and how it can improve efficiency in your operation.

Contact us

I would like to be contacted about